Table of Contents

Advantages of Using Universal Hoist Double Main Beam Gantry Cranes

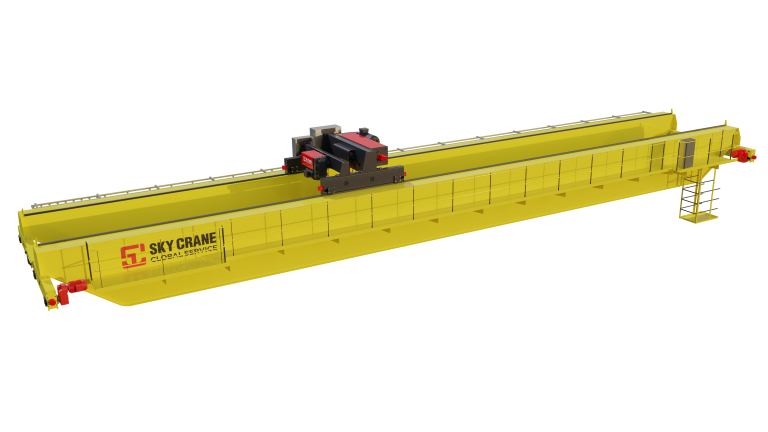

Universal hoist double main beam gantry cranes are a popular choice for many industries due to their versatility and efficiency. These cranes are designed to handle heavy loads with ease, making them ideal for a wide range of applications. In this article, we will discuss the advantages of using universal hoist double main beam gantry cranes and why they are a smart investment for any business.

One of the main advantages of universal hoist double main beam gantry cranes is their ability to lift and move heavy loads with precision and ease. These cranes are equipped with powerful hoists that can lift weights ranging from a few tons to several hundred tons. This makes them ideal for lifting and moving heavy machinery, equipment, and materials in a variety of industrial settings.

Another advantage of universal hoist double main beam gantry cranes is their flexibility and mobility. These cranes can be easily moved and positioned to different locations within a facility, allowing for efficient and seamless operation. This flexibility is especially useful in industries where space is limited or where the layout of the facility may change frequently.

In addition to their lifting and moving capabilities, universal hoist double main beam gantry cranes are also known for their durability and reliability. These cranes are built to withstand heavy use and harsh working conditions, making them a long-lasting and cost-effective solution for businesses. With proper maintenance and care, these cranes can last for many years, providing a reliable and efficient lifting solution for any business.

Universal hoist double main beam gantry cranes are also designed with safety in mind. These cranes are equipped with a range of safety features, such as overload protection, emergency stop buttons, and safety locks, to ensure the safety of both operators and the surrounding environment. This focus on safety makes universal hoist double main beam gantry cranes a trusted choice for businesses looking to prioritize the well-being of their employees and assets.

Furthermore, universal hoist double main beam gantry cranes are easy to operate and maintain. These cranes are designed with user-friendly controls and intuitive interfaces, making them accessible to operators of all skill levels. Additionally, these cranes require minimal maintenance and upkeep, reducing downtime and ensuring that they are always ready for use when needed.

In conclusion, universal hoist double main beam gantry cranes offer a range of advantages that make them a smart investment for any business. From their lifting and moving capabilities to their flexibility, durability, and safety features, these cranes are a reliable and efficient solution for a wide range of industrial applications. With their ease of operation and low maintenance requirements, universal hoist double main beam gantry cranes are a cost-effective and practical choice for businesses looking to improve their lifting and handling capabilities.

How to Choose the Right Universal Hoist Double Main Beam Gantry Crane for Your Needs

When it comes to choosing the right universal hoist double main beam gantry crane for your needs, there are several factors to consider. These cranes are essential for lifting and moving heavy loads in a variety of industries, so it’s important to select the right one for your specific requirements. In this article, we will discuss some key considerations to keep in mind when choosing a universal hoist double main beam gantry crane maker.

First and foremost, it’s important to consider the capacity of the crane. Universal hoist double main beam gantry cranes come in a range of capacities, so you’ll need to determine how much weight you will be lifting on a regular basis. Make sure to choose a crane that can handle the maximum weight you anticipate lifting, as overloading a crane can be dangerous and lead to accidents.

Another important factor to consider is the span of the crane. The span is the distance between the two legs of the gantry crane, and it will determine the maximum width of the area that the crane can cover. Make sure to measure the space where the crane will be used to ensure that you choose a crane with the appropriate span for your needs.

In addition to capacity and span, you’ll also need to consider the height of lift required for your operations. Universal hoist double main beam gantry cranes come in various heights, so make sure to choose a crane that can lift your loads to the required height. Keep in mind that the height of lift will also affect the overall stability of the crane, so it’s important to choose a crane that is well-suited to your specific lifting requirements.

When selecting a universal hoist double main beam gantry crane maker, it’s important to choose a reputable and experienced manufacturer. Look for a company that has a proven track record of producing high-quality cranes that are built to last. You’ll want to choose a maker that offers a warranty on their products and provides excellent customer service in case you encounter any issues with your crane.

It’s also important to consider the features and options available with the crane. Some universal hoist double main beam gantry cranes come with additional features such as adjustable height, variable speed controls, and remote operation capabilities. Consider your specific needs and choose a crane that offers the features that will make your operations more efficient and effective.

In conclusion, choosing the right universal hoist double main beam gantry crane maker is essential for ensuring the safety and efficiency of your lifting operations. Consider factors such as capacity, span, height of lift, manufacturer reputation, and features when making your decision. By taking the time to carefully evaluate your needs and choose a crane that meets them, you can ensure that your operations run smoothly and safely.

Maintenance Tips for Universal Hoist Double Main Beam Gantry Cranes

Universal hoist double main beam gantry cranes are essential equipment in various industries for lifting and moving heavy loads. These cranes are designed to provide efficient and safe lifting operations, but like any other machinery, they require regular maintenance to ensure optimal performance and longevity.

One of the key maintenance tips for universal hoist double main beam gantry cranes is to inspect the crane regularly. This includes checking for any signs of wear and tear, such as cracks, corrosion, or loose bolts. It is important to address any issues promptly to prevent further damage and ensure the safety of the crane operators and the surrounding environment.

In addition to visual inspections, it is also important to perform regular maintenance tasks, such as lubricating moving parts and checking the hoist and trolley for proper alignment. Proper lubrication helps reduce friction and wear on the crane components, while ensuring that the hoist and trolley are properly aligned helps prevent accidents and damage to the crane.

Another important maintenance tip for universal hoist double main beam gantry cranes is to keep the crane clean. Dust, dirt, and debris can accumulate on the crane components, leading to increased wear and potential malfunctions. Regular cleaning of the crane, including the hoist, trolley, and main beam, helps prevent these issues and ensures that the crane operates smoothly and efficiently.

It is also important to inspect the electrical components of the crane regularly. This includes checking the wiring, connections, and controls for any signs of damage or wear. Faulty electrical components can lead to malfunctions and pose a safety hazard, so it is important to address any issues promptly and have them repaired by a qualified technician.

| Nr. | Name |

| 1 | LD electric single beam crane |

| 2 | Single – girder Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Regularly testing the crane’s safety features is another important maintenance tip for universal hoist double main beam gantry cranes. This includes testing the emergency stop button, limit switches, and overload protection system to ensure that they are functioning properly. Testing these safety features helps prevent accidents and ensures the safety of the crane operators and the surrounding environment.

In addition to regular maintenance tasks, it is also important to have the crane inspected by a qualified technician at least once a year. A professional inspection helps identify any potential issues that may not be visible during routine maintenance tasks and ensures that the crane is in compliance with safety regulations and standards.

By following these maintenance tips, universal hoist double main beam gantry crane makers can ensure that their cranes operate efficiently and safely. Regular inspections, maintenance tasks, and professional inspections help prevent accidents, reduce downtime, and extend the lifespan of the crane. Proper maintenance is essential for the safe and efficient operation of universal hoist double main beam gantry cranes, and should not be overlooked.