Table of Contents

Benefits of Using NL Manual Chain Hoist Maker for Heavy Lifting

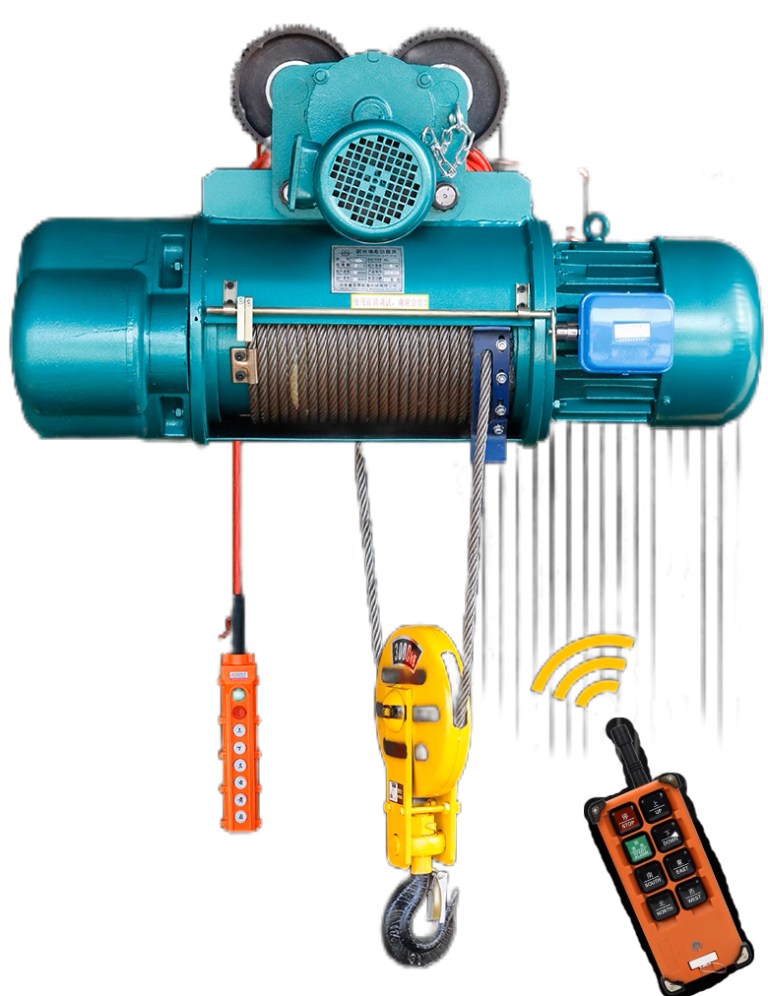

When it comes to heavy lifting, having the right equipment is essential to ensure the safety of workers and the successful completion of tasks. One such piece of equipment that is commonly used for heavy lifting is the NL manual chain hoist maker. This tool is designed to make lifting heavy loads easier and more efficient, while also reducing the risk of injury to workers.

One of the key benefits of using an NL manual chain hoist maker is its versatility. These hoists are capable of lifting a wide range of weights, making them suitable for a variety of applications. Whether you need to lift a few hundred pounds or several tons, an NL manual chain hoist maker can handle the job with ease. This versatility makes them a valuable tool for industries such as construction, manufacturing, and warehousing.

In addition to their versatility, NL manual chain hoist makers are also known for their durability and reliability. These hoists are built to withstand the rigors of heavy lifting, and are designed to last for years with proper maintenance. This means that you can rely on your NL manual chain hoist maker to perform consistently, even in the most demanding work environments.

Another benefit of using an NL manual chain hoist maker is its ease of use. These hoists are designed to be user-friendly, with simple controls that make them easy to operate. This means that workers can quickly learn how to use an NL manual chain hoist maker, reducing the need for extensive training and ensuring that tasks can be completed efficiently.

Furthermore, NL manual chain hoist makers are also known for their safety features. These hoists are equipped with a range of safety mechanisms, such as overload protection and emergency stop buttons, to help prevent accidents and injuries. This means that workers can operate an NL manual chain hoist maker with confidence, knowing that they are protected from potential hazards.

| Nr. | Name |

| 1 | QD OVERHEAD CRANE WITH HOOK CAP.5-800/150T |

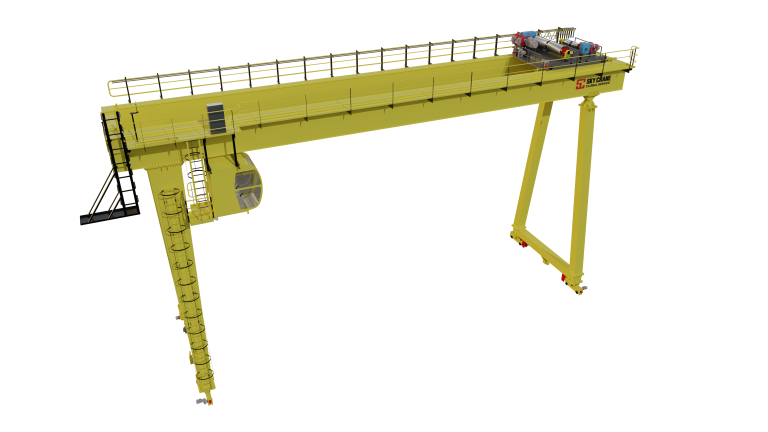

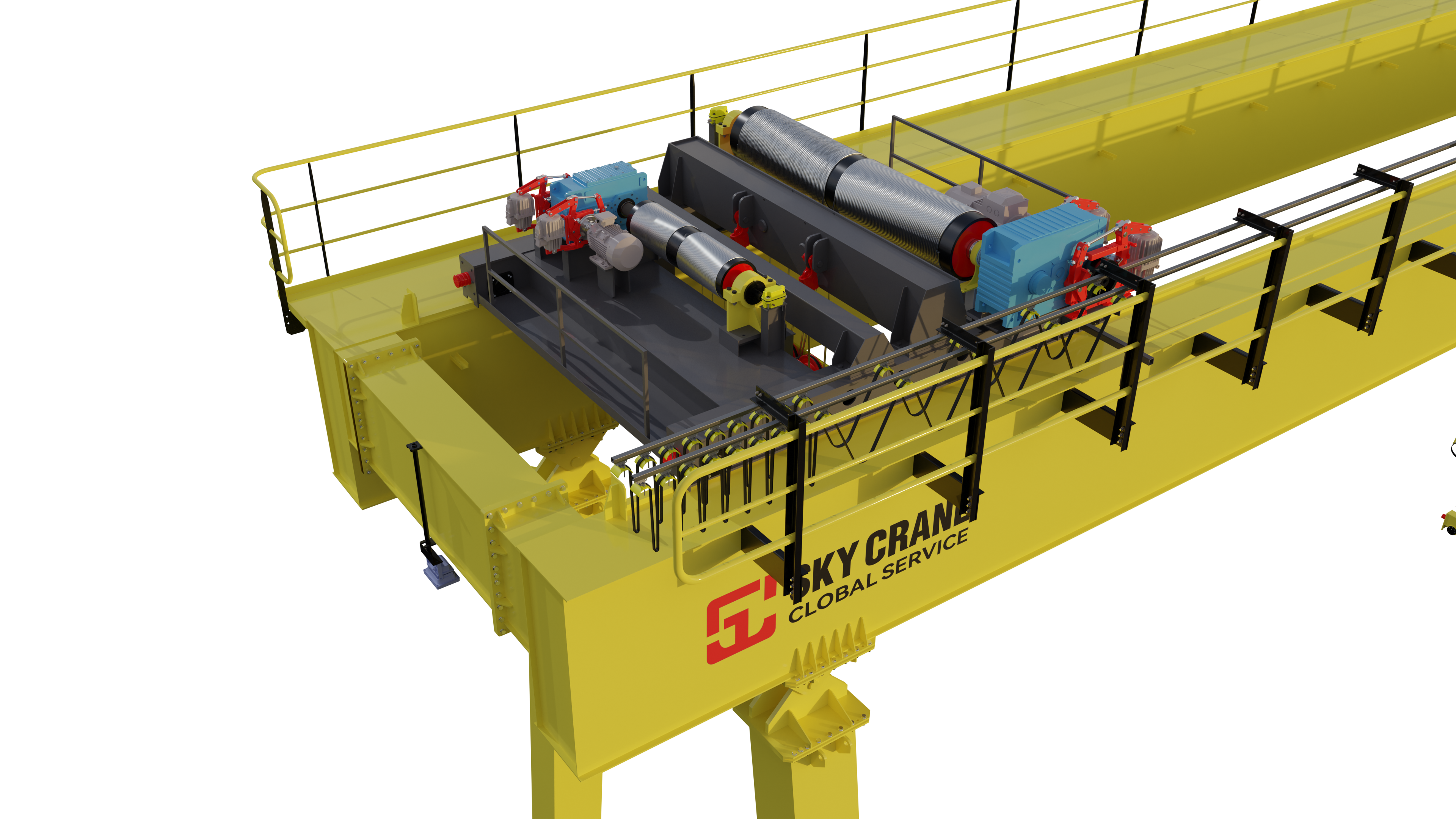

| 2 | Double – girder Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

In addition to their safety features, NL manual chain hoist makers are also designed to be compact and portable. This makes them easy to transport and set up, allowing workers to use them in a variety of locations. Whether you need to lift heavy loads in a confined space or at a remote job site, an NL manual chain hoist maker can be easily moved to where it is needed.

Overall, the benefits of using an NL manual chain hoist maker for heavy lifting are clear. From their versatility and durability to their ease of use and safety features, these hoists are an essential tool for any industry that requires heavy lifting. By investing in an NL manual chain hoist maker, you can improve efficiency, reduce the risk of injury, and ensure the successful completion of tasks.

How to Properly Maintain and Extend the Lifespan of NL Manual Chain Hoist Maker

NL manual chain hoists are essential tools in various industries for lifting and moving heavy loads. To ensure the safety and efficiency of these hoists, proper maintenance is crucial. In this article, we will discuss how to properly maintain and extend the lifespan of NL manual chain hoists.

First and foremost, it is important to regularly inspect the hoist for any signs of wear and tear. Check the chain for any signs of damage, such as kinks, twists, or stretched links. Inspect the hooks for any cracks or deformities. Make sure that all nuts and bolts are securely fastened. Any issues should be addressed immediately to prevent further damage and ensure the safety of the hoist.

In addition to regular inspections, proper lubrication is essential for the smooth operation of the hoist. Apply a high-quality lubricant to the chain and other moving parts to reduce friction and wear. Be sure to follow the manufacturer’s recommendations for the type and frequency of lubrication. Over-lubrication can attract dirt and debris, leading to premature wear and damage.

Another important aspect of maintenance is proper storage of the hoist when not in use. Store the hoist in a clean, dry environment away from moisture and extreme temperatures. Avoid storing the hoist near chemicals or other corrosive substances that could damage the hoist. Proper storage will help prevent rust and corrosion, extending the lifespan of the hoist.

Regularly test the hoist to ensure that it is functioning properly. Perform load tests to check the hoist’s capacity and safety features. Test the brakes to ensure they are working correctly. If any issues are detected during testing, do not use the hoist until the problem has been resolved. Regular testing will help identify any potential issues before they become serious problems.

Proper training is also essential for the safe operation of NL manual chain hoists. Ensure that all operators are properly trained on how to use the hoist correctly and safely. Provide refresher training as needed to keep operators up to date on best practices and safety procedures. Proper training will help prevent accidents and prolong the lifespan of the hoist.

In conclusion, proper maintenance is essential for extending the lifespan of NL manual chain hoists. Regular inspections, lubrication, proper storage, testing, and training are all key components of a comprehensive maintenance program. By following these guidelines, you can ensure the safety and efficiency of your hoist and maximize its lifespan. Remember, a well-maintained hoist is a safe hoist.