Table of Contents

Benefits of Customized Manual Single Beam Cranes

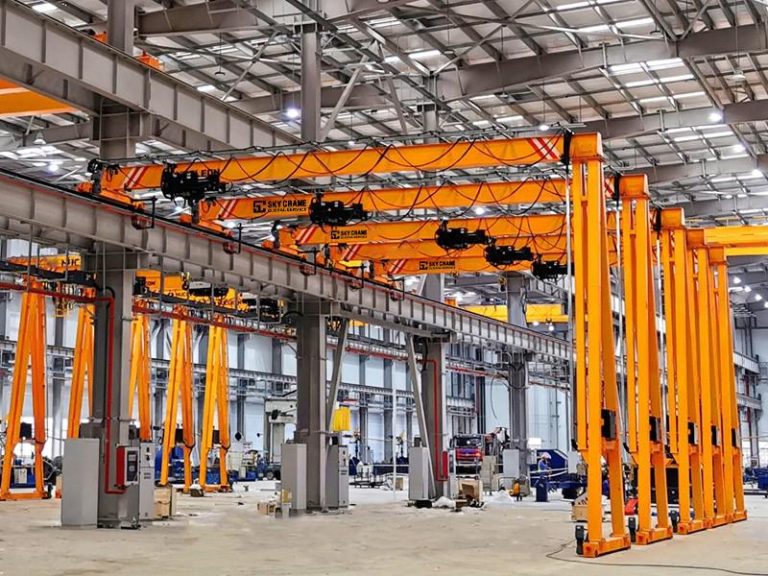

Manual single beam cranes are essential equipment in various industries for lifting and moving heavy loads. These cranes are versatile, cost-effective, and easy to operate, making them a popular choice for many businesses. However, not all manual single beam cranes are created equal. To meet the specific needs of different industries, customization is often required. In China, there are manufacturers that specialize in providing customized manual single beam cranes to meet the unique requirements of their clients.

One of the key benefits of customized manual single beam cranes is that they can be tailored to fit the specific needs of a particular industry or application. Whether it’s a specific lifting capacity, span length, or lifting height, a customized crane can be designed to meet these requirements. This level of customization ensures that the crane is optimized for the specific tasks it will be used for, increasing efficiency and productivity.

Another benefit of customized manual single beam cranes is that they can be designed to fit the available space in a facility. In many cases, standard cranes may not fit the layout of a workspace, leading to inefficiencies and safety hazards. By customizing a crane to fit the available space, businesses can maximize their operational efficiency and ensure a safe working environment for their employees.

Customized manual single beam cranes also offer the advantage of improved safety features. By incorporating specific safety features such as overload protection, emergency stop buttons, and anti-collision systems, customized cranes can help prevent accidents and injuries in the workplace. These safety features can be tailored to meet the specific safety requirements of a particular industry, ensuring compliance with safety regulations and standards.

In addition to safety features, customized manual single beam cranes can also be designed with ergonomic features to improve operator comfort and efficiency. By incorporating features such as adjustable controls, ergonomic seating, and easy-to-use interfaces, customized cranes can help reduce operator fatigue and improve productivity. This can lead to a more efficient and productive work environment, ultimately benefiting the bottom line of a business.

Furthermore, customized manual single beam cranes can be designed with advanced technology and automation features to further enhance their performance. By incorporating features such as remote control operation, automated load sensing, and real-time monitoring systems, customized cranes can offer increased precision and efficiency in lifting and moving operations. This level of automation can help businesses streamline their operations and reduce labor costs, ultimately improving their overall competitiveness in the market.

Overall, the benefits of customized manual single beam cranes are clear. From tailored design to improved safety features, ergonomic enhancements, and advanced technology, customized cranes offer a range of advantages for businesses looking to optimize their lifting and moving operations. In China, there are manufacturers that specialize in providing customized manual single beam cranes to meet the specific needs of their clients. By investing in a customized crane, businesses can improve their operational efficiency, safety, and productivity, ultimately leading to a more successful and competitive business.

Factors to Consider When Customizing a Manual Single Beam Crane

When it comes to selecting a manual single beam crane for your industrial needs, customization is often the key to ensuring that the crane meets all of your specific requirements. With so many options available on the market, it can be overwhelming to choose the right crane for your business. That’s where customization comes in – allowing you to tailor the crane to your exact specifications.

One of the first factors to consider when customizing a manual single beam crane is the lifting capacity. This is perhaps the most important aspect of the crane, as it determines how much weight the crane can safely lift and move. It is crucial to accurately assess the maximum weight that the crane will need to handle in order to select the appropriate lifting capacity. Choosing a crane with a higher lifting capacity than necessary can lead to unnecessary costs, while selecting a crane with a lower lifting capacity can compromise safety and efficiency.

Another important factor to consider is the span of the crane. The span refers to the distance between the two supporting columns of the crane, and it is essential to ensure that the crane can cover the entire working area. Customizing the span of the crane allows you to optimize the layout of your facility and maximize the efficiency of the crane.

In addition to lifting capacity and span, it is also important to consider the height of lift when customizing a manual single beam crane. The height of lift refers to the maximum height at which the crane can lift and lower loads. It is crucial to accurately assess the height requirements of your facility in order to select a crane that can safely and efficiently handle the lifting tasks.

Customizing the control system of the crane is another important factor to consider. The control system determines how the crane is operated, and there are various options available, including pendant control, radio control, and cabin control. Selecting the right control system for your specific needs can improve the safety and efficiency of the crane operation.

When customizing a manual single beam crane, it is also important to consider the environment in which the crane will be operating. Factors such as temperature, humidity, and corrosive substances can impact the performance and longevity of the crane. Customizing the crane with appropriate protective measures, such as special coatings or insulation, can help to ensure that the crane operates effectively in challenging environments.

Finally, it is essential to consider the reputation and experience of the manufacturer when customizing a manual single beam crane. Working with a reputable manufacturer with a proven track record of delivering high-quality cranes can give you peace of mind that your customized crane will meet your expectations. China Best Manufacturer is a leading manufacturer of manual single beam cranes, offering customized solutions to meet the unique needs of each customer.

In conclusion, customizing a manual single beam crane is a crucial step in ensuring that the crane meets all of your specific requirements. By considering factors such as lifting capacity, span, height of lift, control system, environment, and manufacturer reputation, you can customize a crane that is safe, efficient, and reliable for your industrial needs. China Best Manufacturer is your trusted partner in customizing manual single beam cranes to optimize your operations.

Top Features to Look for in a Manual Single Beam Crane from China’s Best Manufacturer

When it comes to selecting a manual single beam crane, it is essential to choose a reliable and reputable manufacturer. China has become a hub for crane production, with many manufacturers offering a wide range of options to suit various needs. However, not all manufacturers are created equal, and it is crucial to look for certain features when selecting a manual single beam crane from China’s best manufacturer.

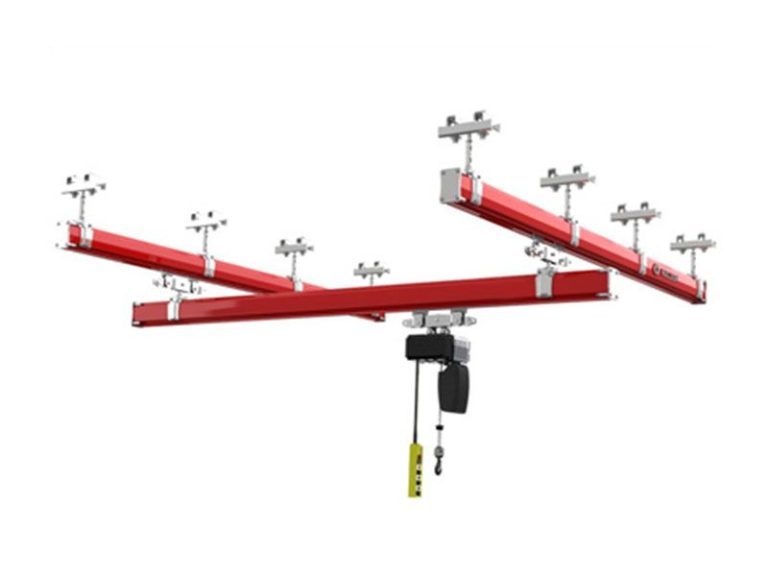

One of the top features to look for in a manual single beam crane is customization options. A reputable manufacturer will offer the ability to customize the crane to meet specific requirements. This can include adjusting the lifting capacity, span length, and lifting height to suit the needs of the application. Customization ensures that the crane will perform optimally and efficiently in the intended environment.

In addition to customization options, it is important to look for a manual single beam crane that is built with high-quality materials. China’s best manufacturers use top-grade steel and components to ensure the durability and longevity of the crane. High-quality materials also contribute to the safety and reliability of the crane, reducing the risk of accidents and breakdowns.

Another key feature to consider is the design and construction of the crane. China’s best manufacturers employ skilled engineers and technicians to design and build manual single beam cranes that are robust and efficient. The design should be optimized for maximum performance and ease of use, with features such as smooth operation, precise control, and minimal maintenance requirements.

Furthermore, it is essential to look for a manual single beam crane that complies with international safety standards. China’s best manufacturers adhere to strict safety regulations and standards to ensure the safety of operators and workers. This includes features such as overload protection, emergency stop buttons, and safety devices to prevent accidents and injuries.

Ease of installation and maintenance is another important feature to consider when selecting a manual single beam crane. China’s best manufacturers design cranes that are easy to install and maintain, reducing downtime and increasing productivity. The crane should come with clear instructions for installation and operation, as well as easy access to components for maintenance and repairs.

Lastly, it is crucial to look for a manual single beam crane that offers excellent after-sales support. China’s best manufacturers provide comprehensive customer service, including technical support, training, and spare parts availability. This ensures that the crane will continue to perform at its best over its lifespan, maximizing the return on investment for the buyer.

| Serial Number | Products |

| 1 | LDP electric single beam |

| 2 | Rubber – tired Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

In conclusion, when selecting a manual single beam crane from China’s best manufacturer, it is important to look for key features such as customization options, high-quality materials, efficient design, safety compliance, ease of installation and maintenance, and excellent after-sales support. By choosing a crane that meets these criteria, buyers can ensure that they are investing in a reliable and durable piece of equipment that will meet their lifting needs for years to come.