Table of Contents

Benefits of Using Manual Single Beam Cranes in Custom Factory Settings

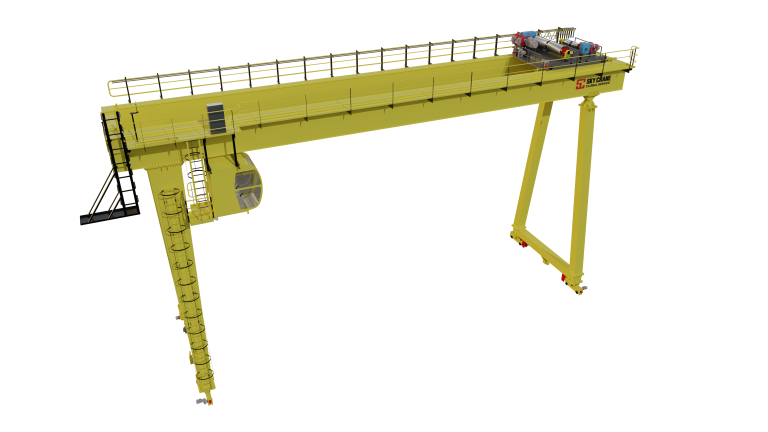

Manual single beam cranes are an essential tool in custom factory settings, providing a cost-effective and efficient solution for lifting and moving heavy loads. These cranes are designed to be operated manually, making them ideal for smaller factories or workshops where space and budget constraints may limit the use of larger, more complex machinery. Despite their simplicity, manual single beam cranes offer a range of benefits that make them a valuable asset in any custom factory setting.

One of the key advantages of using manual single beam cranes is their versatility. These cranes can be easily customized to suit the specific needs of a factory, with options for different lifting capacities, beam lengths, and heights. This flexibility allows for greater efficiency in handling a variety of loads, from small components to larger machinery. In addition, manual single beam cranes can be easily moved and repositioned within a factory, making them a versatile and adaptable solution for changing production needs.

Another benefit of using manual single beam cranes is their ease of operation. Unlike more complex machinery that requires specialized training to operate, manual single beam cranes can be operated by any factory worker with minimal training. This simplicity not only reduces the risk of accidents and injuries but also increases productivity by allowing for quick and efficient lifting and moving of loads. In addition, manual single beam cranes are designed for easy maintenance, with simple components that can be easily replaced or repaired as needed.

In custom factory settings where space is at a premium, manual single beam cranes offer a compact and efficient solution for lifting and moving heavy loads. These cranes are typically mounted on a single beam that can be easily installed in a variety of locations, including above workstations or production lines. This compact design allows for maximum use of floor space, while still providing the lifting capacity needed to handle heavy loads. In addition, manual single beam cranes can be easily integrated with other factory equipment, such as conveyors or storage systems, to create a seamless and efficient production process.

One of the most significant benefits of using manual single beam cranes in custom factory settings is their cost-effectiveness. These cranes are typically more affordable than larger, more complex machinery, making them a practical choice for smaller factories or workshops with limited budgets. In addition, manual single beam cranes require minimal installation and maintenance costs, further reducing the overall cost of ownership. Despite their lower cost, manual single beam cranes offer a high level of performance and reliability, making them a valuable investment for any custom factory setting.

In conclusion, manual single beam cranes are a versatile, efficient, and cost-effective solution for lifting and moving heavy loads in custom factory settings. Their simplicity, versatility, ease of operation, and compact design make them an ideal choice for smaller factories or workshops with limited space and budget constraints. By investing in manual single beam cranes, factory owners can improve productivity, reduce the risk of accidents and injuries, and create a more efficient and streamlined production process.

How to Choose the Right Manual Single Beam Crane for Your Custom Factory

When it comes to setting up a custom factory, one of the most important decisions you will have to make is choosing the right equipment to ensure smooth and efficient operations. One key piece of equipment that is essential for many factories is a manual single beam crane. These cranes are versatile and can be customized to meet the specific needs of your factory. In this article, we will discuss how to choose the right manual single beam crane for your custom factory.

First and foremost, it is important to consider the weight capacity of the crane. You will need to determine the maximum weight that the crane will need to lift in order to ensure that it is capable of handling your factory’s workload. It is always better to choose a crane with a higher weight capacity than you think you will need, as this will allow for future growth and expansion of your operations.

| Serial Number | Article Name |

| 1 | QD OVERHEAD CRANE WITH HOOK CAP.5-800/150T |

| 2 | Single – girder Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Another important factor to consider when choosing a manual single beam crane is the span length. The span length refers to the distance between the two supporting columns of the crane. It is important to choose a crane with a span length that is appropriate for the size of your factory and the layout of your workspace. A crane with a span length that is too short may not be able to reach all areas of your factory, while a crane with a span length that is too long may take up unnecessary space.

In addition to weight capacity and span length, it is also important to consider the lifting height of the crane. The lifting height refers to the maximum height that the crane can lift materials to. It is important to choose a crane with a lifting height that is suitable for the height of your factory and the types of materials that you will be lifting. A crane with a lifting height that is too low may not be able to reach all areas of your factory, while a crane with a lifting height that is too high may be unnecessary and costly.

When choosing a manual single beam crane for your custom factory, it is also important to consider the type of materials that you will be lifting. Different cranes are designed to handle different types of materials, so it is important to choose a crane that is suitable for the specific needs of your factory. For example, if you will be lifting heavy machinery or equipment, you will need a crane with a higher weight capacity and lifting height.

Finally, it is important to consider the reputation of the manufacturer when choosing a manual single beam crane for your custom factory. It is important to choose a crane from a reputable manufacturer that has a history of producing high-quality, reliable equipment. This will ensure that your crane is durable and long-lasting, reducing the need for costly repairs and replacements in the future.

In conclusion, choosing the right manual single beam crane for your custom factory is a crucial decision that will impact the efficiency and productivity of your operations. By considering factors such as weight capacity, span length, lifting height, material type, and manufacturer reputation, you can ensure that you choose a crane that meets the specific needs of your factory. Investing in a high-quality crane will pay off in the long run, as it will help to streamline your operations and improve overall productivity.