Table of Contents

Beneficium Usura Funis Funis obstruit in Industrial Factories

Quam ad elige ius Wire Funebri Clausus pro Factory

Sustentacionem Tips pro filum Funem obstruit Factory Occasus

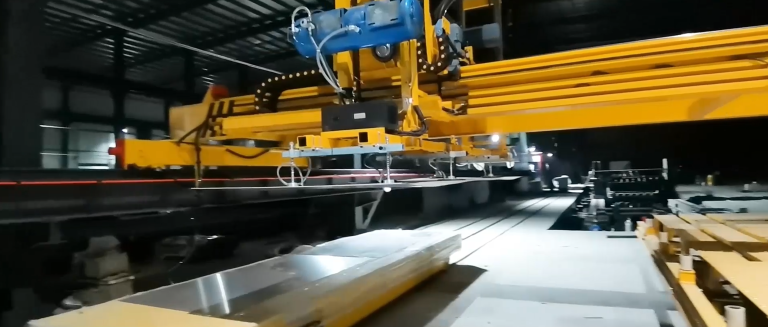

Funiculi fili caudices essentiales partes sunt in uncinis officinarum, ad onera levanda et movenda onera. Hi cuneos e trochlea vel fasciculo in replo insidentes hamo aut vinculo ad oneris applicandi consistunt. Propria conservatio funiculi funiculi crucialis est ut operationem suam salvam et efficacem in ambitus industriae conservet.

No.

Product Name

QD DESINE CRUERIS CUM HUNC CAP.5-800/150T

| MH eculeus gruis | brunculus europaeus-stylus |

| 1 | Portus grus |

| 2 | Una e clavis sustentationis munerum pro funiculi filum, quod inspicientia regularis est. Inspiciendo scandalum signa indumenti, damni, corrosionis essentialis est ad impedienda accidentia et longitudinis apparatum invigilandum. Quaslibet rimas, anfractus, vel deformationes in artus, fasciculum, vel hamum quaeras, sicut hae in obstructionum firmitatem et salutem componi possunt.

damno. Quaere fila fractis, kinks, vel corrosio in funem filum, quod hae restem debilitare possunt et ad defectum sub onere ducunt. Reponere aliquem funem filum laesum statim ne accidentia et operationem securum claudat. Aliud magnum negotium sustentationis pro funiculi filum lubricationis est. Propria lubricatio manipulorum et gestuum essentialis est minuere frictionem et induere, prolongare vitam scandali. Utere qualitas princeps ducatus a fabricante commendatus et applicate regulariter ut lenis clausulae operatio. Semper aestimationem oneris stipis reprehendo, et maximam facultatem a fabrica specificatam numquam excedens. Scandalum obruendum ducere potest ad defectum casusque calamitosos, ideo magni momenti est ut semper utatur intra suam aestimationem facultatem. Si graviore onere levare debes, trunco utere cum superiori facultate ad salutem tuendam. Propria repositio funiculi funiculi magni momenti est etiam ad victum suum. Condite caudices in area munda, arida, et bene ventilata, ne corrosio et damnum inferatur. Vitare caudices prope oeconomiam, umorem, vel extremas temperaturas, sicut hae materias degradare possunt et integritatem scandali componere. Cum usura funiculi funis utens, semper praecepta fabrica et normas tutae operationis sequetur. Truncum inspice ante quemque usum, et numquam trunco utere qui signa gerunt vel damni ostendit. Cura ut onus stipi recte adnectitur et clausus ad structuram stabili stabiliendam antequam quaelibet onera tollat securus. In fine, caudices funerum filum filum proprium est ut in uncinis officinas tuta et efficax operatio conservetur. Iusta inspectio, lubricatio, tabularium clavis sustentationis munia sunt quae adiuvare possunt ad impedienda accidentia et vitae instrumenta prolongantur. Sequentes has apicibus sustentationem et normas, salutem et fidem funiculi funiculi in officina tua efficere potes. |

| 3 | European-style crane |

| 4 | Harbour crane |

One of the key maintenance tasks for wire rope blocks is regular inspection. Inspecting the block for signs of wear, damage, or corrosion is essential to prevent accidents and ensure the longevity of the equipment. Look for any cracks, bends, or deformations in the frame, sheave, or hook, as these can compromise the block’s strength and safety.

In addition to visual inspection, it is important to check the wire rope for any signs of wear or damage. Look for broken strands, kinks, or corrosion on the wire rope, as these can weaken the rope and lead to failure under load. Replace any damaged wire rope immediately to prevent accidents and ensure the block’s safe operation.

Another important maintenance task for wire rope blocks is lubrication. Proper lubrication of the sheave and bearings is essential to reduce friction and wear, prolonging the life of the block. Use a high-quality lubricant recommended by the manufacturer and apply it regularly to ensure smooth operation of the block.

Regularly check the block’s load rating and never exceed the maximum capacity specified by the manufacturer. Overloading the block can lead to catastrophic failure and accidents, so it is important to always use the block within its rated capacity. If you need to lift a heavier load, use a block with a higher capacity to ensure safety.

Proper storage of wire rope blocks is also important for their maintenance. Store the blocks in a clean, dry, and well-ventilated area to prevent corrosion and damage. Avoid storing the blocks near chemicals, moisture, or extreme temperatures, as these can degrade the materials and compromise the block’s integrity.

When using wire rope blocks, always follow the manufacturer’s instructions and guidelines for safe operation. Inspect the block before each use, and never use a block that shows signs of wear or damage. Ensure that the load is properly attached to the block and that the block is securely anchored to a stable structure before lifting any loads.

In conclusion, proper maintenance of wire rope blocks is essential to ensure their safe and efficient operation in factory settings. Regular inspection, lubrication, and storage are key maintenance tasks that can help prevent accidents and prolong the life of the equipment. By following these maintenance tips and guidelines, you can ensure the safety and reliability of wire rope blocks in your factory.