Table of Contents

European Electric Single Beam Cranes: Customization Options from Leading Chinese Factories

European electric single beam cranes have gained significant traction in various industries due to their efficiency, reliability, and versatility. These cranes are particularly favored for their ability to handle a wide range of lifting tasks in confined spaces, making them ideal for warehouses, manufacturing facilities, and construction sites. However, the demand for specific features and functionalities has led to an increasing interest in customized solutions. Leading Chinese factories have recognized this trend and are now offering tailored options to meet the unique requirements of European clients.

One of the primary advantages of sourcing electric single beam cranes from Chinese manufacturers is the ability to customize designs according to specific operational needs. These factories are equipped with advanced technology and skilled engineers who can modify crane specifications, including load capacity, span length, and lifting height. This flexibility allows businesses to optimize their lifting operations, ensuring that the cranes can handle the exact loads and dimensions required for their projects. Furthermore, customization extends beyond mere dimensions; clients can also request specific features such as remote control systems, safety mechanisms, and enhanced mobility options.

In addition to structural modifications, the choice of materials and components plays a crucial role in the customization process. Chinese manufacturers often provide options for high-quality materials that enhance durability and performance. For instance, clients can select between different grades of steel or aluminum, depending on the weight and environmental conditions the crane will face. Moreover, the integration of advanced electrical components, such as variable frequency drives and energy-efficient motors, can significantly improve the crane’s operational efficiency. This level of customization not only meets the immediate needs of businesses but also contributes to long-term cost savings through reduced energy consumption and maintenance requirements.

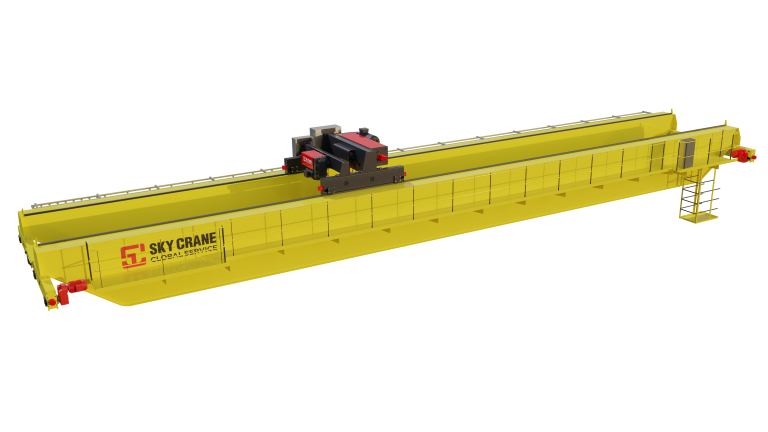

Moreover, the aesthetic aspect of electric single beam cranes is not overlooked in the customization process. European clients often have specific branding requirements, and leading Chinese factories are adept at incorporating these elements into the crane design. This can include custom paint colors, logos, and other branding features that align with the client\\u2019s corporate identity. Such attention to detail not only enhances the visual appeal of the equipment but also reinforces brand recognition in the marketplace.

Another significant benefit of working with Chinese manufacturers is their ability to provide comprehensive support throughout the customization process. From the initial design phase to the final installation, these factories often offer extensive consultation services. This collaborative approach ensures that clients are fully informed about their options and can make educated decisions regarding their crane specifications. Additionally, many factories provide after-sales support, including maintenance services and spare parts availability, which further enhances the overall customer experience.

As the demand for electric single beam cranes continues to grow in Europe, the importance of customization cannot be overstated. Leading Chinese factories are well-positioned to meet this demand by offering tailored solutions that cater to the diverse needs of various industries. By leveraging advanced technology, high-quality materials, and a commitment to customer satisfaction, these manufacturers are not only enhancing the functionality of electric single beam cranes but also contributing to the overall efficiency and productivity of businesses across Europe. In conclusion, the collaboration between European clients and Chinese manufacturers in customizing electric single beam cranes represents a significant advancement in lifting technology, ensuring that businesses can operate effectively in an increasingly competitive landscape.

Top Chinese Manufacturers of European Electric Single Beam Cranes: A Comprehensive Guide

In the realm of material handling equipment, European electric single beam cranes have gained significant traction due to their efficiency, reliability, and versatility. As industries across the globe seek to enhance their operational capabilities, the demand for these cranes has surged, prompting a closer examination of the top Chinese manufacturers that specialize in their production. These manufacturers not only adhere to stringent quality standards but also offer customization options to meet specific client requirements, thereby ensuring that businesses can optimize their operations effectively.

One of the leading manufacturers in this sector is Dongqi Crane, renowned for its commitment to innovation and quality. With a robust portfolio that includes a variety of electric single beam cranes, Dongqi Crane has established itself as a trusted name in the industry. Their cranes are designed with advanced technology, ensuring high performance and safety. Furthermore, the company offers tailored solutions, allowing clients to specify dimensions, load capacities, and additional features, which enhances the crane’s functionality in diverse operational environments.

| Serial Number | Name |

| 1 | QZ OVERHEAD CRANE WITH GRAB CAP.5-20T |

| 2 | Double – girder Gantry Crane |

| 3 | European-style crane |

| 4 | Harbour crane |

Another prominent player is Weihua Group, which has made significant strides in the manufacturing of electric single beam cranes. Weihua Group is recognized for its state-of-the-art production facilities and a dedicated research and development team that focuses on continuous improvement. Their cranes are not only built to meet international standards but are also customizable to cater to the unique needs of various industries, including construction, manufacturing, and logistics. This adaptability has positioned Weihua Group as a preferred supplier for many businesses looking to enhance their material handling capabilities.

In addition to these manufacturers, XCMG is another key contender in the market. Known for its extensive range of construction machinery, XCMG has also ventured into the production of electric single beam cranes. The company prides itself on its rigorous quality control processes and innovative design approaches. By offering customizable options, XCMG ensures that its cranes can be tailored to specific applications, thus providing clients with the flexibility they require to optimize their operations. Their commitment to quality and customer satisfaction has earned them a solid reputation both domestically and internationally.

Moreover, the company Anshan Heavy Duty Mining Machinery Group is noteworthy for its specialization in heavy-duty equipment, including electric single beam cranes. Anshan Heavy Duty Mining Machinery Group focuses on producing robust and durable cranes that can withstand the rigors of demanding industrial environments. Their ability to customize cranes according to client specifications further enhances their appeal, making them a go-to manufacturer for businesses that require heavy lifting solutions.

As the market for electric single beam cranes continues to evolve, these Chinese manufacturers are at the forefront of innovation and customization. Their ability to produce high-quality cranes that meet international standards while offering tailored solutions is a testament to their expertise and commitment to excellence. By collaborating with these manufacturers, businesses can not only enhance their operational efficiency but also ensure that they are equipped with the best tools to meet their specific needs.

In conclusion, the landscape of European electric single beam crane manufacturing is significantly influenced by top Chinese manufacturers. With their focus on quality, innovation, and customization, companies like Dongqi Crane, Weihua Group, XCMG, and Anshan Heavy Duty Mining Machinery Group are well-positioned to meet the growing demands of industries worldwide. As businesses seek to improve their material handling capabilities, partnering with these manufacturers can provide the necessary support and solutions to achieve operational success.

The Benefits of Sourcing Customized Electric Single Beam Cranes from China for European Markets

Sourcing customized electric single beam cranes from China for European markets presents a multitude of benefits that can significantly enhance operational efficiency and cost-effectiveness. As industries across Europe continue to evolve, the demand for specialized equipment that meets specific operational requirements has surged. Chinese manufacturers have emerged as key players in this arena, offering tailored solutions that align with the unique needs of European businesses.

One of the primary advantages of sourcing from China is the ability to obtain highly customized products. Chinese factories are renowned for their flexibility in production, allowing them to adapt designs and specifications based on client requirements. This customization can encompass various aspects, including load capacity, span length, and operational features. By collaborating closely with manufacturers, European companies can ensure that the cranes they procure are not only fit for purpose but also enhance their overall productivity.

Moreover, the cost-effectiveness of sourcing from China cannot be overstated. Chinese manufacturers benefit from economies of scale, which often translates into lower production costs. This financial advantage allows European businesses to acquire high-quality electric single beam cranes at competitive prices. Additionally, the reduced labor costs in China further contribute to the affordability of these products. Consequently, European companies can allocate their resources more efficiently, investing in other critical areas of their operations while still obtaining top-tier equipment.

In addition to cost savings, the quality of Chinese-manufactured cranes has seen significant improvements over the years. Many factories have adopted international quality standards and certifications, ensuring that their products meet stringent safety and performance criteria. This commitment to quality is particularly important for European markets, where regulatory compliance is paramount. By sourcing from reputable Chinese manufacturers, European companies can rest assured that they are investing in reliable and durable equipment that will withstand the rigors of daily operations.

Furthermore, the technological advancements in crane manufacturing in China have led to the development of innovative features that enhance operational efficiency. Many Chinese factories are at the forefront of integrating advanced technologies, such as automation and smart controls, into their crane designs. These innovations not only improve the functionality of electric single beam cranes but also contribute to safer and more efficient operations. As European industries increasingly prioritize automation and digitalization, sourcing cranes equipped with the latest technology becomes a strategic advantage.

Another significant benefit of sourcing from China is the ability to leverage the extensive supply chain networks that have been established over the years. Chinese manufacturers often have access to a wide range of components and materials, enabling them to produce cranes that are not only customized but also readily available. This streamlined supply chain can lead to shorter lead times and quicker delivery, which is crucial for European companies looking to minimize downtime and maintain productivity.

In conclusion, sourcing customized electric single beam cranes from China offers European markets a unique opportunity to enhance their operational capabilities while benefiting from cost savings and technological advancements. The combination of customization, affordability, quality assurance, and access to innovative features positions Chinese manufacturers as valuable partners for European businesses. As industries continue to adapt to changing demands, the strategic decision to source from China can lead to significant competitive advantages in the marketplace. By embracing this approach, European companies can ensure they are well-equipped to meet the challenges of the future.