Table of Contents

Advantages of Using Fixed Cantilever Cranes in Industrial Settings

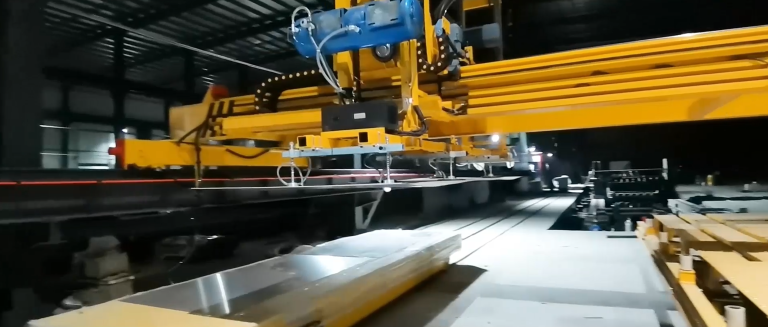

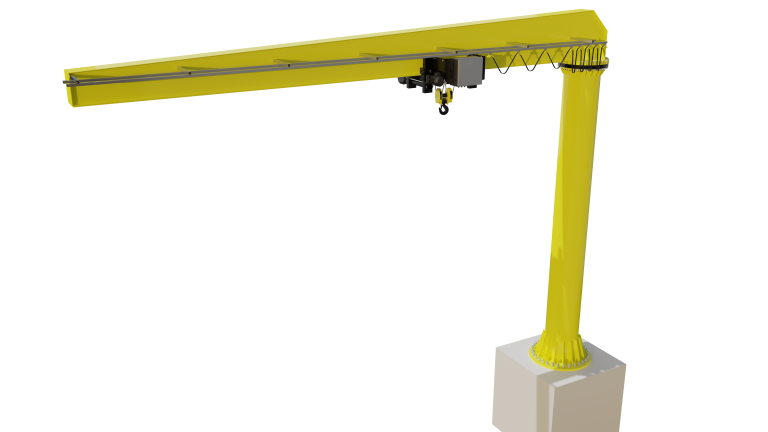

Fixed cantilever cranes are an essential piece of equipment in many industrial settings. These cranes are designed to provide a stable and reliable lifting solution for heavy loads in a variety of applications. In this article, we will explore the advantages of using fixed cantilever cranes in industrial settings and highlight some of the best Chinese factories that produce these high-quality machines.

One of the primary advantages of using fixed cantilever cranes is their ability to provide a high level of lifting capacity. These cranes are designed to handle heavy loads with ease, making them ideal for lifting and moving large objects in industrial settings. Whether you are working in a warehouse, manufacturing facility, or construction site, a fixed cantilever crane can help you safely and efficiently lift and transport heavy materials.

Another advantage of using fixed cantilever cranes is their versatility. These cranes can be customized to meet the specific needs of your operation, whether you need a crane with a longer reach, a higher lifting capacity, or specialized features such as a rotating boom or a telescoping arm. This flexibility makes fixed cantilever cranes a valuable tool for a wide range of industrial applications.

In addition to their lifting capacity and versatility, fixed cantilever cranes are also known for their durability and reliability. These cranes are built to withstand the rigors of daily use in industrial settings, and they are designed to provide years of dependable service with minimal maintenance. This reliability is essential in industrial operations where downtime can be costly, making fixed cantilever cranes an excellent investment for businesses looking to maximize productivity and efficiency.

When it comes to choosing a fixed cantilever crane for your operation, it is essential to select a high-quality machine from a reputable manufacturer. Chinese factories are known for producing some of the best fixed cantilever cranes in the world, with a reputation for quality craftsmanship and innovative design. Some of the best Chinese factories that produce fixed cantilever cranes include XCMG, SANY, and Zoomlion, among others.

XCMG is one of the largest construction machinery manufacturers in China, with a long history of producing high-quality cranes for a variety of applications. Their fixed cantilever cranes are known for their robust construction, advanced technology, and reliable performance, making them a popular choice for industrial operations around the world.

SANY is another leading Chinese manufacturer of fixed cantilever cranes, with a reputation for producing durable and efficient machines that can handle even the most demanding lifting tasks. SANY cranes are designed to provide superior performance and reliability, making them a top choice for businesses looking for a high-quality lifting solution.

Zoomlion is also a well-known Chinese manufacturer of fixed cantilever cranes, with a focus on innovation and technology. Their cranes are designed to provide maximum efficiency and safety, with features such as advanced control systems, precision engineering, and high-quality materials. Zoomlion cranes are trusted by businesses worldwide for their performance and reliability in industrial settings.

In conclusion, fixed cantilever cranes are an essential tool for lifting and moving heavy loads in industrial settings. These cranes offer a high level of lifting capacity, versatility, durability, and reliability, making them an excellent investment for businesses looking to improve productivity and efficiency. Chinese factories such as XCMG, SANY, and Zoomlion are known for producing some of the best fixed cantilever cranes in the world, with a reputation for quality craftsmanship and innovative design. When choosing a fixed cantilever crane for your operation, be sure to select a high-quality machine from a reputable manufacturer to ensure years of dependable service and maximum performance.

Top Features to Look for When Choosing a Fixed Cantilever Crane

When it comes to choosing a fixed cantilever crane for your industrial needs, there are several key features that you should consider. Fixed cantilever cranes are a popular choice for many industries due to their versatility and efficiency. However, not all fixed cantilever cranes are created equal, and it’s important to choose a crane that meets your specific requirements. In this article, we will discuss some of the top features to look for when choosing a fixed cantilever crane from the best Chinese factories.

| No. | Article Name |

| 1 | 5~400T NEW-TYPE OVERHEAD CRANE WITH HOOK |

| 2 | L-type gantry crane |

| 3 | European-style crane |

| 4 | Harbour crane |

One of the most important features to consider when choosing a fixed cantilever crane is its lifting capacity. The lifting capacity of a crane refers to the maximum weight that it can safely lift and move. It’s crucial to choose a crane with a lifting capacity that meets your specific needs. If you choose a crane with a lifting capacity that is too low, you may not be able to lift and move heavy loads efficiently. On the other hand, if you choose a crane with a lifting capacity that is too high, you may be wasting money on unnecessary features.

Another important feature to consider when choosing a fixed cantilever crane is its reach. The reach of a crane refers to the distance that it can extend horizontally from its base. The reach of a crane is important because it determines the area that the crane can cover. If you need to move heavy loads over a large area, you will need a crane with a longer reach. On the other hand, if you only need to move loads over a small area, a crane with a shorter reach may be sufficient.

In addition to lifting capacity and reach, it’s also important to consider the durability and reliability of a fixed cantilever crane. A crane is a significant investment, and you want to choose a crane that will last for many years to come. Look for cranes that are made from high-quality materials and have a reputation for reliability. It’s also a good idea to choose a crane from a reputable manufacturer with a track record of producing high-quality products.

Safety is another crucial feature to consider when choosing a fixed cantilever crane. Cranes can be dangerous if not used properly, so it’s important to choose a crane that is equipped with safety features to protect both workers and equipment. Look for cranes that have features such as overload protection, emergency stop buttons, and safety guards to prevent accidents.

Finally, consider the cost of the fixed cantilever crane. While it’s important to choose a crane that meets your specific requirements, you also want to make sure that it fits within your budget. Compare prices from different manufacturers and choose a crane that offers the best value for your money.

In conclusion, when choosing a fixed cantilever crane from the best Chinese factories, it’s important to consider features such as lifting capacity, reach, durability, reliability, safety, and cost. By carefully evaluating these features, you can choose a crane that meets your specific needs and provides excellent performance for years to come.

How to Properly Maintain and Extend the Lifespan of Fixed Cantilever Cranes

Fixed cantilever cranes are essential equipment in many industries, providing efficient lifting and moving capabilities for heavy loads. To ensure the longevity and optimal performance of these cranes, proper maintenance is crucial. In this article, we will discuss the best practices for maintaining fixed cantilever cranes and extending their lifespan.

Regular inspections are key to identifying any potential issues before they escalate into major problems. Inspect the crane for signs of wear and tear, such as loose bolts, cracks, or corrosion. Check the electrical components for any damage or malfunction. It is also important to inspect the crane’s structure, including the beams, columns, and connections, to ensure they are in good condition.

Routine lubrication of moving parts is essential to prevent friction and wear. Make sure to use the appropriate lubricant for each component, such as grease for bearings and chains. Regularly check the oil levels in the gearbox and hydraulic system and top up as needed. Proper lubrication will help reduce wear and tear on the crane’s components and extend its lifespan.

Regularly clean the crane to remove dirt, dust, and debris that can cause damage to the equipment. Use a mild detergent and water to clean the crane’s surfaces, including the beams, columns, and electrical components. Pay special attention to areas where dirt and debris can accumulate, such as around the wheels and in the electrical panel. Keeping the crane clean will help prevent corrosion and ensure smooth operation.

Inspect the crane’s safety features, such as limit switches, overload protection, and emergency stop buttons, to ensure they are functioning properly. Test these features regularly to make sure they will work when needed. It is also important to train operators on how to use these safety features correctly and to follow proper operating procedures to prevent accidents and damage to the crane.

In addition to regular maintenance, it is important to address any issues promptly to prevent further damage to the crane. If you notice any signs of wear or malfunction during an inspection, take immediate action to repair or replace the affected components. Ignoring these issues can lead to more extensive damage and costly repairs down the line.

When it comes to maintaining fixed cantilever cranes, prevention is key. By following these best practices for maintenance, you can extend the lifespan of your crane and ensure it continues to operate safely and efficiently. Regular inspections, proper lubrication, cleaning, and addressing issues promptly are essential to keeping your crane in top condition. By investing time and effort in maintenance, you can protect your investment and avoid costly downtime due to equipment failure.